Transshipment strategy: enrich your TOS with new efficient Transshipment stacking strategies

Revolutionizing Container Transshipment: Optimize Your Operations with DMSLOG.Ai’s AI-Driven Solutions. Experience the Future of Port Efficiency Today!

Your terminal today

Your terminal today Your Smart Port tomorrow

Your Smart Port tomorrowTrusted by industry-leading innovators

Join the 1000+ terminals committed to fighting climate change

DMSLOG.Ai proposes a TOS agnostic solution with simplified API integration to plan transshipment containers stacking in the yard and pre-stowage at vessel discharging time.

Those interfaces help the operator trust the AI, measure its savings, and monitor its resource utilization – with the help of live digital twins simulations.

356t CO2

-10%

Historical insight

Yard efficiency analytics

Revolutionize terminal operations with yard view insights

This interface provides an interactive satellite view of the terminal, allowing operators to click for detailed information on blocks, bays, and containers. It integrates key performance data and offers a historical timeline feature for tracking operational changes.

Ship load optimization

Enhance vessel handling with ship view features

Focused on optimizing vessel load distribution and container movement prediction, this interface delivers detailed bay insights and supports both automatic and manual resource allocation.

Optimized distribution

Resource flexibility

Ai is not magic 🪄... it's high-level mathematics 🧮 applied with common sense logic

AI-enhanced vessel loading sequence prediction

Time-labor reduction

Reshuffle minimization

Designing the load sequence for a vessel at a container terminal is a highly labor-intensive task. It involves ensuring that containers are placed on the vessel in compliance with specific vessel constraints. Simultaneously, efforts are made to prevent unproductive moves in the yard, known as reshuffles.

AI-assisted workload forecasting for yard blocks

Planning precision

Task management

The transhipment stacking strategy considers the anticipated workload within a designated block during a set timeframe, involving tasks such as storing or retrieving containers.

However, the precise workload is uncertain during the planning phase. To address this uncertainty, machine learning techniques are employed to predict the workload accurately.

AI block allocation system

Distance reduction

Space maximization

Block allocation powered by AI refers to the use of Artificial Intelligence algorithms and techniques to optimize the allocation of containers to a block in port operations.

AI-powered block allocation systems consider various factors such as information about the vessel, berth information, yard layout, container inventory levels, and container characteristics.

Using this data, the AI determines the optimal block allocation that minimizes the distance required to transport containers and maximizes the use of available space and resources.

AI-optimized pre-stowage strategy development

Stability enhancement

Safety assurance

An AI-powered optimization system for pre-stowage employs advanced algorithms to create an optimal stowage plan. It takes into account different constraints, including container size and type, as well as ship stability considerations.

The model for pre-stowage guarantees an efficient and optimized arrangement of containers into the vessel, ensuring both ship stability, maximum slot utilizationand minimizing re-stowage while meeting the safety requirements.

AI-guided container positioning strategy

Positioning streamlining

ASC coordination

The AI system conducts an evaluation of different elements when a block is chosen, including TOS-related filters/segregations and predicted dwell time, in order to suggest the best position for each container.

The proposed stacking strategy also takes into account efficient coordination between ASCs engaged in containers handling activities within the given block.

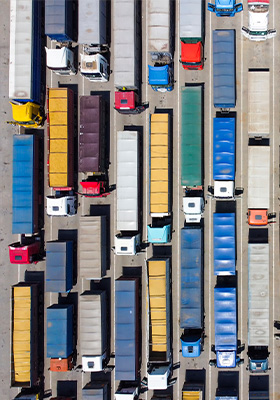

AI in predicting external truck traffic

Congestion reduction

Yard planning

The goal in this AI is the forecasting of external truck movements and traffic patterns coming to a container terminal.

This prediction is achieved by analyzing various information such as external truck visit historical data, vehicles booking system historical data, traffic information inside the terminal, weather conditions, and road infrastructure.

Predictive models are developed to estimate truck flow and anticipate potential bottlenecks or delays in areas surrounding the terminal yard blocks. The modeling process can also incorporate geolocation information within the yard, during the construction of predictive features.

AI-enabled dwell time estimation

Yard efficiency

Delay reduction

Dwell time is the period that a container spends within a container terminal in one or more terminal stacks. It is a crucial factor influencing the efficiency and overall performance of maritime logistics operations.

The container dwell time predictions, vessel load sequences and workload per yard block benefit from incorporating some or all of the following data as predictive features:

- Container Cycle Data

- Gate Transaction Data

- Manifest Data

- Customs Clearance data

- TOS Rules and related data

- Equipment Availability

- General Stowage Plan

⚖️ Get compliant with your local and international CO2 regulations.

Intergovernmental Panel on Climate Change, United Nations Climate Change, Organisation for Economic

Co-operation and Development, UN Environment Programme, The European Council, USA Department of Energy…

📈 Our Transshipment performance & ROI

DMSLOG.Ai already has good experience with AI-powered stacking strategies and we can estimate a reasonable range for the expected results.

-0%

Unproductive moves

-0%

Vessel turnaround time

$0K

Minimum direct saved

0t

CO2 direct saved

Transshipment Pricing 🏷️

The terminal subscribes to the Transshipment – and pays monthly based on its volume of containers.

Besides, transporters benefit from advanced features that allow them to reduce their waiting time in lines, facilitate their combined operations and rotate on the terminal more quickly.

$0,1 to 2/TEU *

To automate your VBS

* Prices not contractual: depending on your volume, contract duration, options, specific requirements.

Free access

To make appointments at the terminal

The proof of concept is available as soon as the beta version is released, and already allows the terminal to check the accuracy of DMSLOG.Ai recommendations.

| Month 1 | Data acquisition cleaning & modeling | ||

| Month 3 | Offline simulation (digital twins) | ||

| Month 4 | Online simulation (Digital twins) | ||

| Month 5 | API integration with any TOS | ||

| Month 6 | Validation on the yard |

Our IT, Consulting and Project Management services 🤝

For any project deployment, we support you in the following steps.

5 star expertise on the latest tech

Our Transshipment container stacking and container pre-stowage planning is available in…

[gtranslate]

This deployment process is done in 3 main steps.

Phase 1 – Dual Operation:

Initially, you’ll continue operating your current Vehicle Booking System (VBS) while we deploy our new system. This phase ensures there is no disruption in your terminal’s operations. Our team will work closely with yours to set up the new VBS in parallel, focusing on integrating it seamlessly with your existing infrastructure.

Phase 2 – Hybrid Testing:

In this phase, both the old and new VBS will be operational concurrently. This ‘hybrid system’ allows us to conduct real-world testing of the new VBS with a select group of carriers. It’s a crucial step to ensure the new system functions as intended and to identify and resolve any potential issues. This phase also provides an opportunity for your staff and carriers to familiarize themselves with the new system without fully depending on it.

Phase 3 – Full Transition and Closure:

Once the new VBS is thoroughly tested and validated, we’ll transition all transporter activities to it. During this phase, the old VBS will be phased out. We ensure a smooth transition where all transporters are now using the new system effectively. Following the successful implementation, the old VBS will be closed. However, we will securely store all historical data from the old system to ensure that no critical information is lost and can be accessed if needed.

Yes, a CMS is integrated into our Vehicle Booking System.

This detailed breakdown provides an in-depth look at how the CMS module integrated into the VBS enhances communication and operational efficiency between the terminal and the carriers community.

For Terminal Managers – Automatic Updates:

- The following automatic features simplifies terminal operations and ensures timely information dissemination.

For Carriers – Community Space Features:

- Vessel Information Access: Enabling carriers to view detailed vessel information, including Estimated Time of Arrival (ETA) and Estimated Time of Departure (ETD).

- Container Tracking: Offering carriers the ability to track containers at each step, similar to an Amazon order tracking system, including status updates within the vessel and terminal (or on the way to the terminal, when the truck TMS is connected to the VBS via API).

- Financial Information and Transactions: Providing information on Last Free Day, storage guarantees, payments due, and fees, sourced directly from the Terminal Operating System (TOS). Carriers can conveniently pay these charges using various payment methods like Credit Card, Visa, Mastercard, GooglePay, and ApplePay.

- Truck Turnaround Time Estimations: Availability of a chart displaying estimated Truck Turnaround Times for the current and upcoming days, aiding carriers in planning and logistics.

Public and Private Access

- Access Control: Allowing for tailored information sharing based on the terminal’s and carriers’ needs.

Yes, our VBS can work without the Ai layers – even if the best logistics optimizations come from the Ai features.

Contact us for more details, it will be a pleasure to deploy our Vehicle Booking System on your terminal.

However, a Vehicle Booking System with Ai Integration has several benefits:

- Advanced Logistics Optimization: Utilizing AI algorithms, the system offers superior logistics management, optimizing container handling and vehicle scheduling.

- Predictive Analytics: AI capabilities enable predictive modeling for better forecasting and decision-making.

- Enhanced Efficiency: The AI layer streamlines operations, reducing wait times and improving turnaround.

- Data-Driven Insights: AI tools provide valuable insights for continuous improvement and strategic planning.

without any longer project deployment (they both need 4 to 6 month).