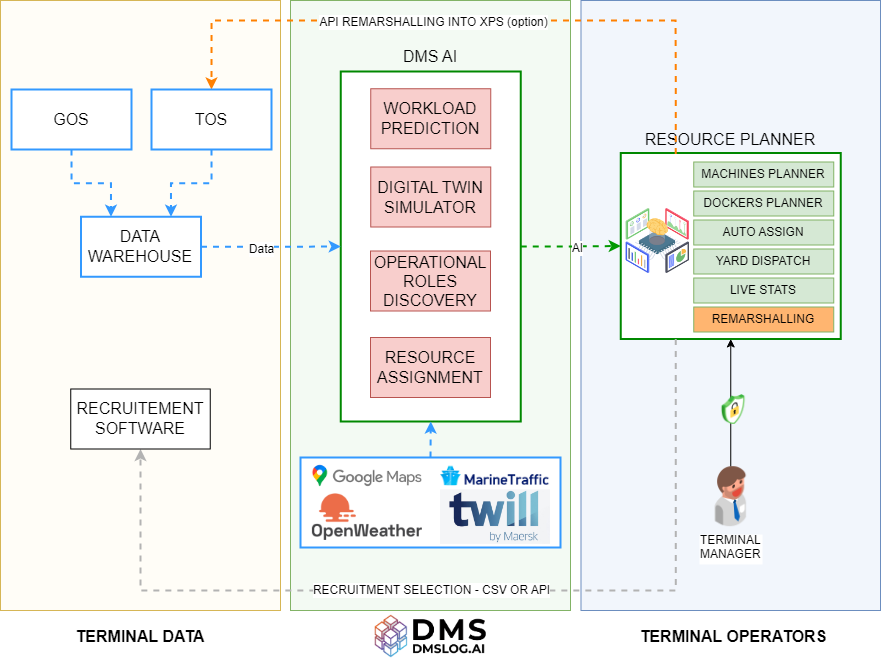

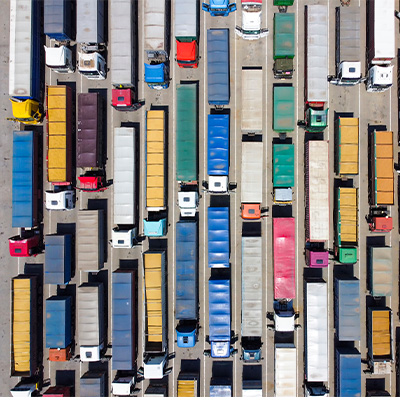

Save unneeded resources on your container terminal with our resources planner

Our unique resources planner estimates the number of container moves expected > calculates the machines and dockers needed > matches the machines-dockers regarding your HR rules > and shows you how much you saved compared to a similar day.

Without resources planner

Without resources planner With DMS resources planner

With DMS resources plannerTrusted by industry-leading innovators

Join the 1000+ terminals committed to fighting climate change

Discover the unique advantages of our container terminal resources planner: Exclusive to DMSLOG.Ai, the power of Combinatorial optimization and machine learning algorithms. Explore our key innovations.

-10% unprod. moves

-10% fuel

-10% CO2

Real-time Insights

unproductive container movements reduction

Live monitoring of some KPI of the current shift in a container terminal is of utmost importance for operational effectiveness and real-time decision-making. This allows terminal managers and supervisors to gain immediate visibility into the terminal’s performance.

Workflow Optimization

...to dynamic working lists

A working list denotes a compilation of containers intended for departure in the upcoming time period.

This list is dynamic and requires preparation during a shift operation and subsequent execution during off-peak working hours. The proactive generation of dynamic working lists during live terminal activity monitoring serves as a strategic initiative to minimize future activity peaks.

Efficient Departure Planning

Activity Peak Minimization

📐 Predictions of container terminal operation workload

DMS Prediction: Interpretation and Feedback Insights

Optimize workflow

Optimize terminal's efficiency

The ability to interpret insights derived from predictive analysis is influential, as it offers a comprehensive grasp of what elements are taken into account in the prediction process and, equally importantly, what factors are not considered (see interface below).

This level of comprehension empowers stakeholders to anticipate potential risks and challenges, providing them with the tools to: :

- proactively address and

- mitigate any potential operational obstacles.

DMS Prediction: Workload Distribution & Yard Cranes Dispatch

Optimized Crane Placement

Proactive Management

Additional indicators that also showcase workload predictions and distribution over yard blocks assist in identifying potential bottlenecks, enabling terminal operators to take preventive measures and streamline operations.

These visualizations not only offer a comprehensive overview of the terminal’s operations but also serve as decision-support tools:

- empowering managers to make informed choices for improving productivity,

- reducing operational bottlenecks, and

- enhancing overall efficiency within the container terminal.

DMS Prediction: A Study of Diverse Scenario Analyses

Strategic Scenario Planning

Decide with Certainty

These simulations encompass alterations in the number of deployed machines during a shift, allowing the user to observe the resultant impacts on variables such as vessel schedule variations, yard crane operations, and quay cranes productivity.

Consequently, this heightened confidence in the decision-making process contributes to better risk management, allowing terminals to proactively

- identify,

- assess, and

- mitigate risks.

From Live Monitoring to Dynamic Working Lists

Efficient Remarshaling

Proactive Peak Management

Dynamic working lists offer a sizable advantage in the realm of terminal operations, particularly in orchestrating effective remarshaling movement recommendations for container preparations.

This strategic utilization of low-peak periods not only optimizes the existing resources but also contributes to a more efficient workflow. It allows terminals to proactively manage the yard, ensuring containers are strategically placed for upcoming movements, thus reducing the need for additional resources in future shifts.

⚖️ Get compliant with your local and international CO2 regulations.

Intergovernmental Panel on Climate Change, United Nations Climate Change, Organisation for Economic

Co-operation and Development, UN Environment Programme, The European Council, USA Department of Energy…

📈 Our container terminal resources planner KPIs

We provide the most powerfull container terminal resources planner on the market.

+0k

tons of CO2

+0

digital twins strategies

+0k

unprod. Moves.

+0M

containers handled

This system has been designed to analyze and process vast amounts of data in real-time, enabling terminal operators to make informed decisions and maximize operational efficiency.

Our Resources planner is configured month #1, tested month #2, and deployed month #3 to get your ROI month #3.

For any project deployment, we support you in the following steps.

5 star expertise on the latest tech

Our container terminal resources planner is available in…

[gtranslate]

In your data we are able to identify similar days to compare and calculate our efficiency of our olanner container terminal resources.

Yes, not only can the recruitment offered by DMS be adjusted manually by an operator, but also access to the platform can be given to any authorized user.

If you have to do your recruitment before 2 p.m. the day before, we ensure that the result of the predictions is optimal at that time.

However, you can always launch a new schedule until the start of your shift.